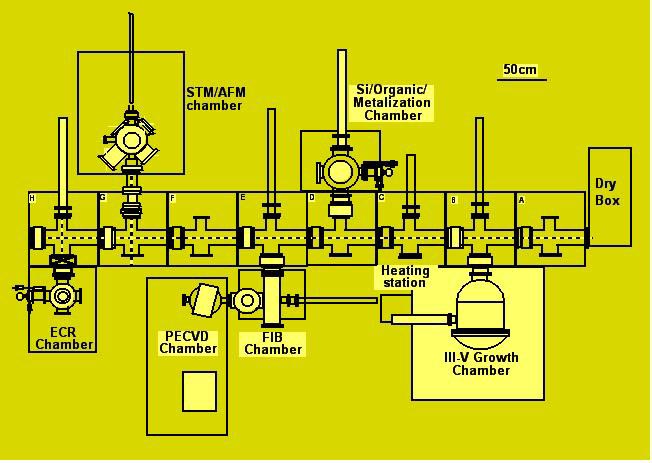

UHV

Interconnected Growth & In-Situ Processing, &

Characterization system:

MBE

Chamber:

The MBE chamber is the heart of the Integrated UHV interconnected

system and is used for fabrication of advanced III-V

(Ga, Al, In arsenides) epitaxical nanostructures (quantum

well, wires, and dots) and state-of-art devices (lasers,

photodetectors, modulators, transistors). A reflection

high-energy electron diffraction (RHEED) system is integrated

on to the chamber that allows in-situ diagnostics and

real-time control on epitaxical growth. The chamber

has standard Knudsen effusion cells for deposition of

Ga, In, Al, and As. Si and Be K-cells are available

for doping of the structures. Additionally, a water-cooled

Arsenic valved cracker is installed on the chamber.

Substrate temperature is measured using an IR pyrometer.

A quadropole mass-analyzer is used to monitor the background

gas species in the chamber. The combination of cryopump,

ion pump, and titanium sublimation pump on the chamber

achieves base pressure in the low E-10 torr range.

AFM-STM Chamber:

This chamber was the first system that integrates STM/AFM

that is UHV connected to an extensive growth and processing

system. A unique design consisting of suspended bellows

achieves vibration isolation of this chamber from the

rest of the system, a key engineering feat that has

enabled us to achieve atomic-resolution on III-V surfaces.

This chamber enables a morphological evolution studies

that look at effects of various types of growth or processing

while avoiding deleterious effects of ambient exposure.

An illustrative example is our studies on the kinetic

pathways of the InAs 3D island formation on GaAs (001).

Cleaning/Metallization/Dielectric

Chamber:

This chamber has quite diverse capability resulting

from three distinct equipment that are mounted: (1)

An electron-beam deposition system that allows deposition

of low vapor pressure materials such as W, Au, Si, fluorides,

oxides etc., (2) a gas-source cell containing a high-temperature

filament which is used for cracking of molecular gases,

and (3) standard Knudsen cells for deposition of low-vapor

pressure materials. The chamber also has RHEED analysis

capability. In our most recent work, we have extensively

used this chamber for semiconductor surface cleaning

using atomic hydrogen with a low thermal budget.

FIB Chamber:

The chamber is equipped with a liquid Ga ion gun and

a nozzle for reactive gas delivery. Nanoscale features

can be fabricated using Ga ions by either purely physical

sputtering or with sputtering assisted chemical etching.

The chamber is capable of patterning semiconductor as

well as dielectrics.

PECVD Chamber:

The chamber is used for deposition of SiO2 and Si3N4.

These dielectrics are typically used either as a mask

layer for further FIB patterning or as surface passivation

layers.

ECR Chamber:

The chamber uses an ECR source for the generation of

reactive ions. The gases connected to this chamber enable

etching of III-arsenides, Si, SiO2, and Si3N4. The chamber

has been designed so that spectroscopic ellipsometry

(SE) measurements can be performed to monitor the processes

in real-time.