|

|

Integrated

Hybrid Nanostructures: Overgrowth on InAs NCQDs

|

|

This

work is supported by: DURINT-01

AFOSR Grant No. F49620-01-1-0474

|

Our

approach to epitaxical integration of NCQDs (schematically

shown in fig. 3 of the introduction) follows a four step

procedure:

1. Preparation of a fresh atomically

smooth GaAs(001) surface via MBE growth.

2. Deposition of NCQDs on the

substrate from the toluene solution in a controlled atmosphere

glove box.

3. Surface cleaning to remove

the organic moieties coming from the NCQD solution and

also the TOP ligand molecules from the NCQD surface.

4. High quality III-V epitaxical

overgrowth.

As a prototypical systemthe we have investigated epitaxical

integration of InAs NCQDs into GaAs matrix. Due to the

reduced thermal stability of the InAs NCQDs compared to

bulk InAs, a consequence of "Kelvin" effect,

steps 3 and 4 have to carried out with the lowest possible

thermal budget consistent with good quality overgrowth.

To minimize the thermal budget during step 3 we carry

out the cleaning with the assistance of H-radical flux.

And for step 4 we employ Migration Enhanced Epitaxy (MEE)

a special MBE based technique which allows high quality

epitaxy at low temperatures. Cleaning under optimized

conditions leads to substantial size-reduction of NCQDs,

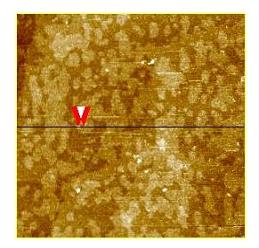

from ~ 4nm starting size to ~ 1nm. Figure 1 shows AFM

measurement of the NCQDs after optimized cleaning.

|

|

|

|

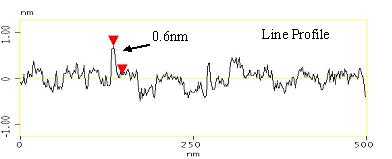

| Figure 1 (a)

AFM image of the NCQDs on GaAs(001) after H-assisted cleaning. (b) Height profile across the line

shown in panel (a).

|

|

To determine the quality

of the epitaxical overgrowth, the MEE growth is done

simultaneously on three types of substrates loaded on

the same holder:

(1) Untreated sample - this

sample is exposed only to the glove-box and serves as

the reference,

(2) Toluene exposed sample,

and

(3) InAs NCQD deposited sample.

The overgrowth consisted of deposition of 1ML InAs followed

by 170 ML of GaAs. The 1 ML InAs layer serves as an

marker to determine the optical quality.

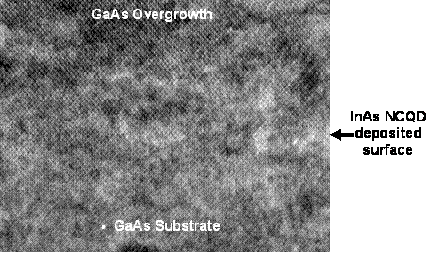

HRTEM and PL studies

were performed to determine the structural and optical

nature of the overgrowth. The cross-sectional HRTEM

image shown in fig. 2 evidences the good structural

quality. Large regions of the sample were examined (compared

to the mean spacing between the NCQDs) and no extended

defects were observed. However, the limitations (spatial

resolution and lack of chemical information) of employed

TEM precludes observation of the embedded ~ 1nm InAs

NCQDs.

|

|

Figure 2 Cross-sectional HRTEM image of overgrowth

on InAs NCQDs.

|

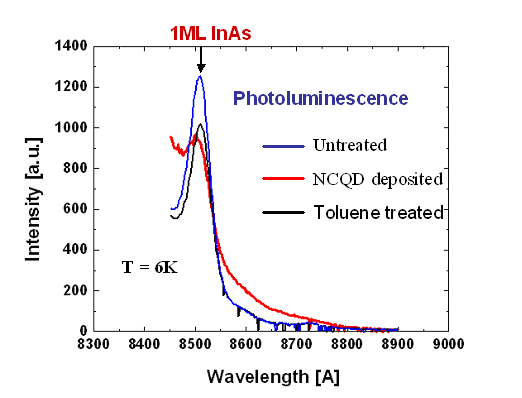

| The

results from optical studies (see in figure 3) show that

the 1ML InAs PL of the toluene-exposed and NCQD-deposited

samples is comparable to that of reference, a result consistent

with the good structural quality. Though we do not see

a clear optical signature from the NCQDs, the NCQD deposited

sample shows a shoulder on the low-energy side of the

1 ML InAs PL peak. The location of this shoulder is qualitatively

consistent with that expected from sub-nm InAs NCQDs.

Following these encouraging results (for details see reference

1), we are proceeding with the obvious next step of using

InAs NCQDs with a larger starting size than the 4nm NCQDs

used in these studies. We have recently succeeded in synthesizing

8nm InAs NCQDs with large yield by using punctuated growth,

a concept that was developed and demonstrated in our lab

in the context of synthesizing the InAs self-assembled

quantum dots (SAQDs) with independent control over their

density and size (reference 2).

|

|

Figure 3 Photoluminescence behavior of the overgrowth

|

References:

1. "Integrated semiconductor nanocrystal and epitaxical

nanostructure systems: structural and optical behavior",

Anupam Madhukar, Siyuan Lu, Atul Konkar, Yi Zhang, Max

Ho, Steven M. Hughes, and A. Paul Alivisatos, Nano Lett.

5, 492 (2005).

2. "Punctuated island growth: An approach to examination

and control of quantum dot density, size, and shape evolution",

I. Mukhametzhanov, Z. Wei, R. Heitz, and A. Madhukar,

Appl. Phys. Lett. 75, 85 (1999)

|

II.1

Study of Energy Transfer

II.2

TEM Study

DURINT

Project

- Nanocrystal/Eptaxial

2D integration

- Surface

Modification (Chemical & Biochemical)

- Nanoscale

Simultaneous Morphological & Optical Imaging

Back to Top

|